Is Inventory Counting the Worst Task in Retail?

| Retail

:format(jpeg))

It’s a fact. One of the worst jobs in retail is inventory counting and stock management.

It’s tedious and can take up large amounts of a store associate’s day.

Whether it’s ensuring the right items have been received or manually counting or scanning items one by one. Doing it accurately is vitally important, but it takes up a lot of valuable time.

:format(jpeg))

We’ve been helping retailers shift tedious tasks to technology for quite a few years, and now we’ve added a new tool to our box that is a step-change for store operations. Offering 10x faster inventory counting and further improving the lives of store associates.

Frontline challenges

These tedious tasks are part of a bigger challenge that retailers are facing at the moment.

Titled ‘The Great Attrition’ or ‘The Great Resignation’’ by some, frontline retail workers have been leaving their positions at an unprecedented rate.

Doing meaningful work, flexibility, compensation and career development are some of the reasons cited on why workers might leave their job in retail.

Attracting the right talent to fill vacant positions and retaining employees are big challenges too.

A recent study from the US Chamber of Commerce found that “even if every unemployed person with experience in the retail industry were employed, the industry would only fill 70% of the vacant jobs.”

Doing meaningful work and empowering employees is something we talk frequently about. We support retailers with our technology in this area so we’ll look a little deeper into it.

There are some inevitable tasks out there that retail workers have to perform.

We wondered what the worst one was…

To get a better understanding, we conducted a straw poll of former retail frontline workers and asked them what the worst store associate task is.

And the results are in.

:format(jpeg))

Top of the list was inventory counting or stock taking.

Manually with pen and paper or scanning items one by one to figure out how much stock you have. Exactly the type of tedious work that is contributing to employees leaving their jobs.

Inventory counting – A numbers game

It’s understandable why inventory counting was voted the worst task. It involves the physical verification of quantities of items held in store. Or put simply, counting.

On the surface you might think counting is pretty easy. And in some situations it is.

But in others, especially for large retailers or small businesses using a barcode inventory system, it is not.

In most situations counting is done one by one. Individually counting or scanning each item or box.

Here are just a few reasons why it is one of the most hated tasks to perform:

- It’s tedious. Scanning and manually counting hundreds of items is pretty dull

- It takes a lot of time

- If you get interrupted or forget your count, you have to start again

- Inventory inaccuracy can be costly for business

One former retail associate who used to work for a fashion store gave us a bit more insight about why inventory counting is so bad.

:format(jpeg))

They were using dedicated scanners which came with its own issues. She said “Quite a few had run out of battery so we only had 2 or 3 to share, so you had to wait your turn.”

She added “It was very hard to know which item you scanned. We couldn’t tell if an item had been scanned twice. We would do the inventory count, then take the scanner to the computer and upload the results. Only then would we find out about any issues.”

When receiving goods, this lack of access to real-time data led to a lot of time being lost.

“The receiving area was quite far from where we docked the devices to sync with the system. And we could only do one lot of scans at a time. So we spent lots of time just walking between the two. I was a sales associate and meant to be on the shop floor supporting customers and selling.”

Count on Scandit

Well the good news is there is a new kid in town. And this kid can count. Quickly.

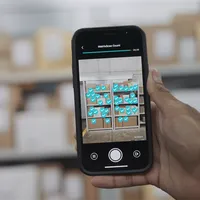

MatrixScan Count is the name.

:format(jpeg))

One of the enablers from our smart data capture platform. It builds on the existing MatrixScan capability of being able to scan multiple barcodes in one sequence.

Learm more about MatrixScan Count

MatrixScan Count is an out-of-the-box scan and count software solution for inventory counting and receiving goods. Store associates can scan and count multiple items simultaneously, using familiar Android or iOS smartphones or tablets.

See how it works here.

Our tests show that an end-to-end inventory counting workflow using MatrixScan Count is ten times faster than scanning barcodes one by one, without suffering accuracy. Can you imagine doing a task that takes an hour one day and then 6 minutes the next?

Store associates can save valuable time and concentrate on other tasks such as shelf management, order fulfilment or customer service.

It can integrate easily with inventory management systems for large or small businesses to provide real-time feedback and actionable alerts to the user using augmented reality so they know exactly what to do next in certain situations.

We’ve spent 6 months developing and testing the user experience to ensure the best possible workflow for employees and minimal to no training requirements. As well as real-time notifications, ergonomics and audio and haptic feedback have been built in to make sure the experience is as seamless as possible.

So save your employees from one of the worst jobs in retail. Empower them to work smarter and faster. Activate their counting speed superpower and watch them fly through inventory counting and receiving goods tasks.

Guide: Transform Your Store Operations App

This guide shows you how to upgrade your current workflows for faster, more efficient operations.